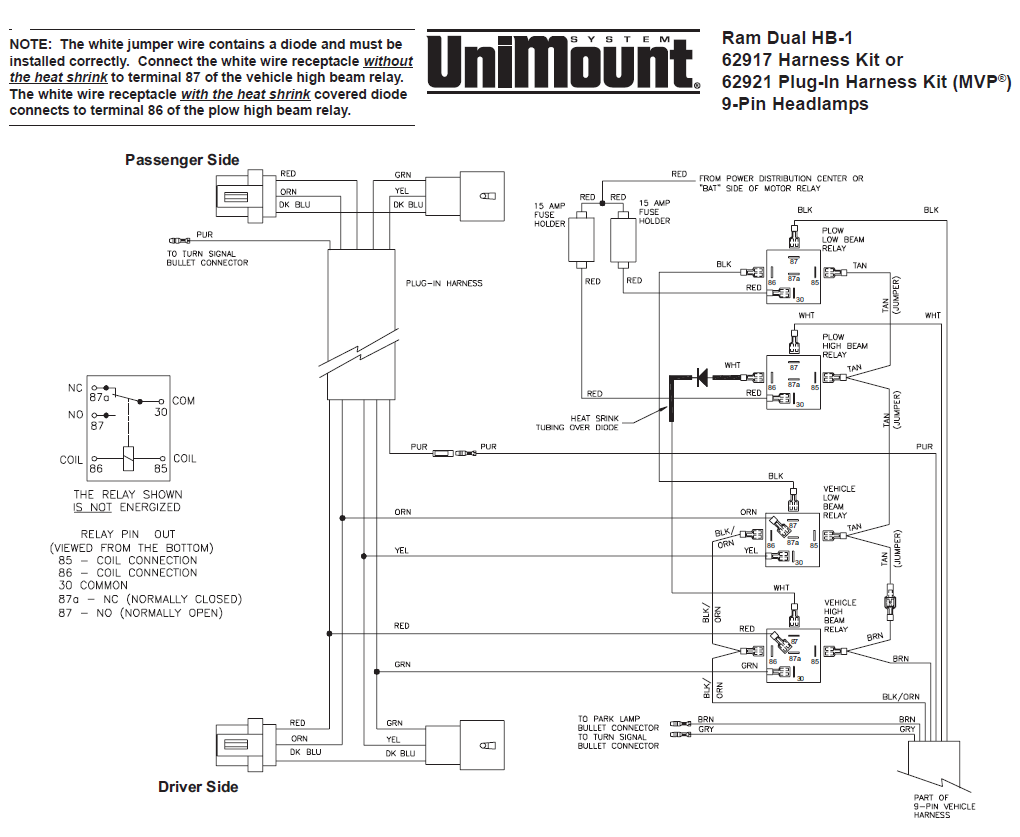

When it comes to working on a Boss plow, understanding the wiring diagram is crucial for ensuring the proper functioning of the headlights. The Boss Plow Headlight Wiring Diagram provides a visual representation of the electrical connections and wire colors, making it easier to troubleshoot and repair any issues that may arise.

Importance of Boss Plow Headlight Wiring Diagram

- Helps in identifying the correct wires for connecting the headlights

- Ensures proper installation and functioning of the headlights

- Aids in troubleshooting electrical problems efficiently

Reading and Interpreting Boss Plow Headlight Wiring Diagram

Reading a Boss Plow Headlight Wiring Diagram may seem daunting at first, but with a little practice, it can become second nature. Here are some tips to help you read and interpret the diagram effectively:

- Identify the key components such as the headlights, wires, connectors, and switches

- Understand the color-coding of the wires to distinguish between positive and negative connections

- Follow the flow of the electrical system to trace the path of the current

Using Boss Plow Headlight Wiring Diagram for Troubleshooting

When faced with electrical problems in your Boss plow headlights, the wiring diagram can be your best friend. Here’s how you can use it for troubleshooting:

- Check for continuity in the wires to ensure there are no breaks or short circuits

- Verify the voltage levels at different points in the circuit to pinpoint the source of the issue

- Refer to the wiring diagram to identify any faulty components that may need replacement

It is important to exercise caution when working with electrical systems and using wiring diagrams. Here are some safety tips to keep in mind:

- Always disconnect the power source before working on any electrical components

- Use insulated tools to prevent electric shock

- Avoid working on wet surfaces or in damp conditions to reduce the risk of electrocution

Boss Plow Headlight Wiring Diagram

boss plow headlight wiring diagram

Boss Plow Headlight Wiring Schematic

Boss Snow Plow Light Wiring Diagram Download – Wiring Diagram Sample

Boss Plow Controller Wiring Diagram – Wiring Digital and Schematic

Understanding Boss Plow Wiring Diagrams | WIREGRAM

Wiring Diagram For Boss Snow Plow: How To Install And Troubleshoot