When it comes to working with electrical systems, having a clear understanding of the Heat Tape Wiring Diagram is crucial. These diagrams provide a visual representation of the electrical connections and components involved in the heat tape system, helping mechanics and technicians troubleshoot, repair, and maintain the system effectively.

Why Heat Tape Wiring Diagrams are Essential

Heat Tape Wiring Diagrams are essential for several reasons:

- They provide a clear overview of the electrical connections and components in the heat tape system.

- They help identify potential issues or faults in the system.

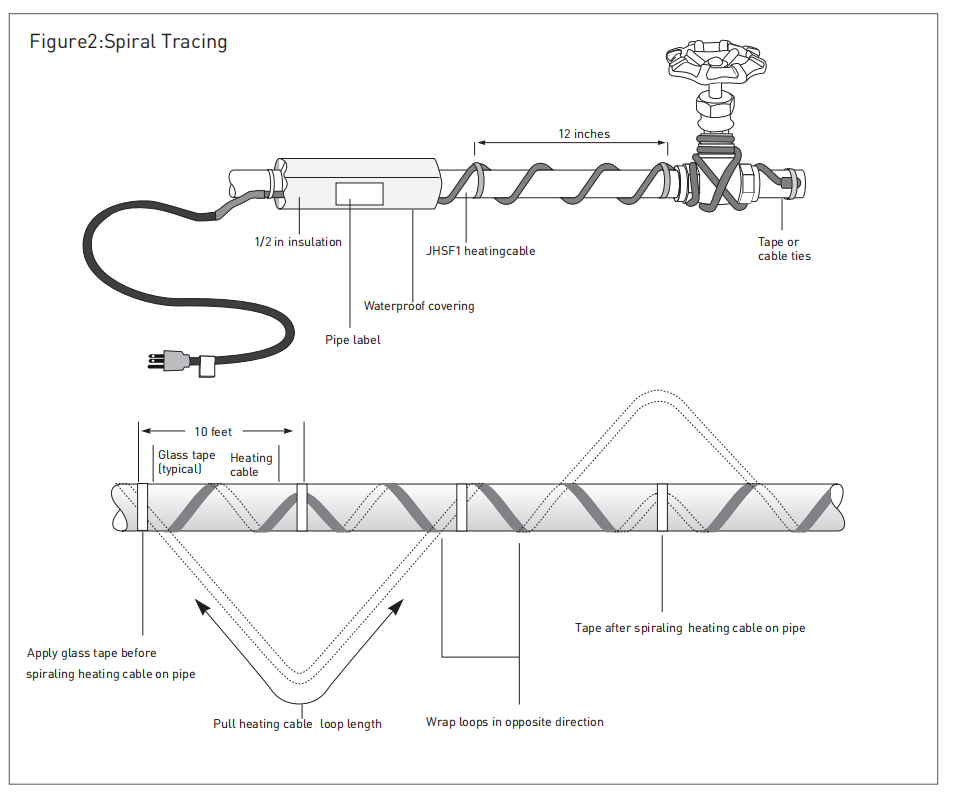

- They guide technicians in properly installing and maintaining the heat tape system.

Reading and Interpreting Heat Tape Wiring Diagrams

Reading and interpreting Heat Tape Wiring Diagrams effectively requires a basic understanding of electrical symbols and circuit diagrams. Here are some tips to help you:

- Familiarize yourself with common electrical symbols used in wiring diagrams.

- Follow the flow of the diagram from power source to components to understand the circuit.

- Pay attention to color codes and labeling to identify wires and connections.

Using Heat Tape Wiring Diagrams for Troubleshooting

Heat Tape Wiring Diagrams are invaluable tools for troubleshooting electrical problems in the heat tape system. Here’s how you can use them effectively:

- Identify the specific component or connection causing the issue.

- Check for continuity and proper voltage levels using a multimeter.

- Refer to the wiring diagram to trace the circuit and pinpoint the problem area.

Importance of Safety

When working with electrical systems and using wiring diagrams, safety should always be a top priority. Here are some safety tips and best practices to keep in mind:

- Always turn off the power supply before working on the system.

- Use insulated tools and wear appropriate personal protective equipment.

- Avoid working on live circuits and seek professional help if needed.

Heat Tape Wiring Diagram

How to install heat tapes on pipe? – HEATIT

How to Use Heat Shrink Tape | Gamma Electronics

Heat Trace Solutions | Omega Engineering CA

Heat Cable Installation – Structure Tech Home Inspections

Heat Tape Wiring Diagram Collection – Wiring Diagram Sample

Heat Tape Wiring Diagram Collection – Wiring Diagram Sample