K Swap Conversion Harness Wiring Diagram

When performing a K swap conversion on your vehicle, having a detailed wiring diagram is essential to ensure a smooth and successful installation. The K swap conversion harness wiring diagram provides a visual representation of the electrical connections needed to integrate the new engine into your vehicle’s existing wiring system. This diagram is a valuable tool that can help you identify and connect the various wires and components correctly.

Why K Swap Conversion Harness Wiring Diagrams are Essential

- Helps to ensure proper integration of the new engine into the vehicle

- Provides guidance on connecting different components and sensors

- Avoids electrical issues and potential damage to the vehicle

- Assists in troubleshooting any wiring problems that may arise

How to Read and Interpret K Swap Conversion Harness Wiring Diagrams

Reading and interpreting a K swap conversion harness wiring diagram may seem daunting at first, but with a little guidance, it can be a straightforward process. Here are some tips to help you effectively understand the diagram:

- Identify the key components and connections on the diagram

- Follow the color codes and symbols to determine the correct wiring connections

- Refer to the legend or key provided to understand the different elements of the diagram

- Take your time to analyze the diagram thoroughly before starting the installation

Using K Swap Conversion Harness Wiring Diagrams for Troubleshooting

In addition to helping with the initial installation, K swap conversion harness wiring diagrams can also be valuable tools for troubleshooting electrical problems. By referring to the diagram, you can easily identify any faulty connections or components that may be causing issues. This can save you time and effort in diagnosing and fixing electrical problems in your vehicle.

Importance of Safety

When working with electrical systems and using wiring diagrams, it is crucial to prioritize safety to prevent accidents and injuries. Here are some safety tips and best practices to keep in mind:

- Always disconnect the battery before working on any electrical components

- Use insulated tools to avoid electrical shocks

- Avoid working on electrical systems in wet or damp conditions

- Double-check all connections before powering up the system

K Swap Conversion Harness Wiring Diagram

K Swap Wiring Harness

K Swap Conversion Harness Wiring Diagram

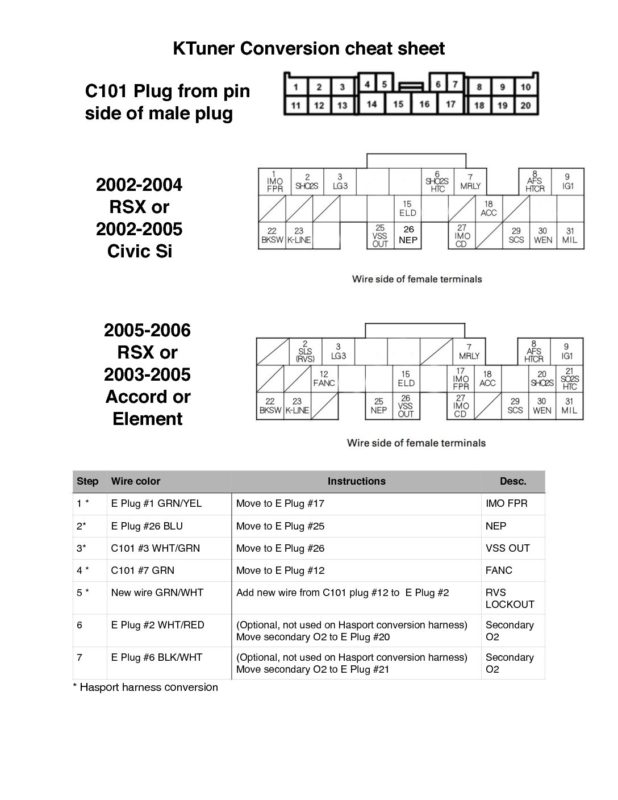

How to Wire Your K Swap Harness for KTuner: – VTEC Academy

K-swap Conversion Harness Wiring Diagram

K Swap Conversion Harness Wiring Diagram

K-swap Conversion Harness Wiring Diagram