When it comes to working on LS engines, having a comprehensive understanding of the wiring system is crucial. One valuable tool that can assist in this process is the LS Bench Harness Wiring Diagram. This diagram provides a detailed layout of the wiring connections and components of the LS engine, making it easier for mechanics to diagnose and repair electrical issues.

Why are LS Bench Harness Wiring Diagrams essential?

LS Bench Harness Wiring Diagrams are essential for several reasons:

- They provide a visual representation of the wiring system, making it easier to identify components and connections.

- They help mechanics understand the electrical layout of the engine, enabling them to troubleshoot and repair issues more efficiently.

- They serve as a guide for proper wiring techniques, ensuring that connections are made correctly and safely.

How to read and interpret LS Bench Harness Wiring Diagrams effectively

Reading and interpreting LS Bench Harness Wiring Diagrams may seem daunting at first, but with some guidance, it can become second nature. Here are some tips to help you effectively navigate these diagrams:

- Start by familiarizing yourself with the key symbols and colors used in the diagram.

- Follow the flow of the wiring diagram from the source (battery) to the components, paying attention to the connections along the way.

- Refer to the legend or key provided with the diagram to understand the meaning of each symbol or color used.

Using LS Bench Harness Wiring Diagrams for troubleshooting electrical problems

LS Bench Harness Wiring Diagrams are invaluable when it comes to troubleshooting electrical problems. Here’s how you can use them effectively:

- Identify the specific circuit or component that is causing the issue on the diagram.

- Trace the wiring connections related to the problematic component to pinpoint any potential faults or breaks in the circuit.

- Use a multimeter to test the continuity and voltage at various points in the circuit, referring back to the diagram for guidance.

Importance of safety when working with electrical systems

Working with electrical systems, including using wiring diagrams, requires a keen focus on safety. Here are some safety tips and best practices to keep in mind:

- Always disconnect the battery before working on any electrical components to prevent the risk of electric shock.

- Avoid working on electrical systems in wet or damp conditions to reduce the risk of short circuits.

- Use insulated tools and wear protective gear, such as gloves and safety goggles, when handling electrical components.

Ls Bench Harness Wiring Diagram

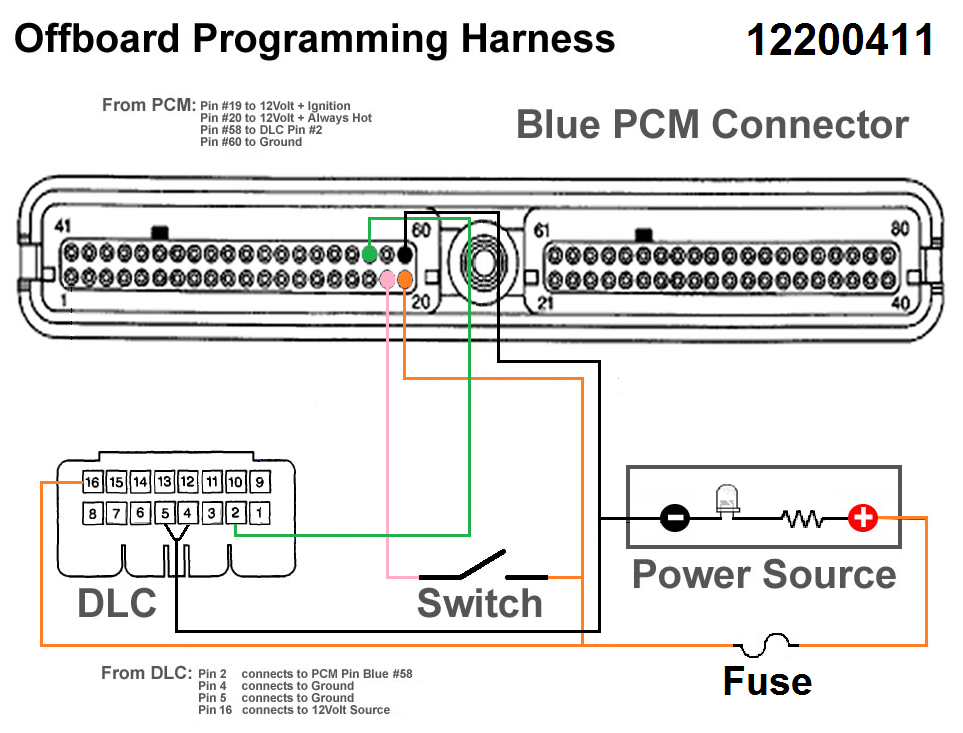

Building a Benchtop PCM Tuning Harness – GM Truck Central

How To DIY: LS Bench Harness for my HP Tuners Programing(15 Years and

How To Make A Ls Wiring Harness

Shop Talk – Episode 7 (Easy how to LS bench harness build) – YouTube

LS Swap Stock Pcm Bench harness | DIY – YouTube

The Ultimate Guide to Ls Standalone Wiring Harness Instructions